- Paint & Coating[10]

- Polymer[2]

- Contact Person : Ms. Wang Terry

- Company Name : Jinhu Color Powder Coating Co., Ltd.

- Tel : 0086-25-57909280

- Fax : 025-57909280

- Address : Jiangsu,NANJING,Hua yuan Road 8#

- Country/Region : China

- Zip : 210042

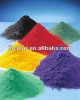

thermosteting spray metallic powder paint

JINHU COLOR POWDER COATING CO.LTD Provides a wide range of powder coating products,inluding

GENERAL TYPES

Epoxy Polyester /Hybrid powder coatingEpoxy Powder CoatingPolyester TGIC -Free powder coatingPolyester TGIC Powder coatingPolyurethane powder coatingFUNCTIONAL TYPES

Anti-gassing Powder Coating for cast steelClear Topcoat Powder CoatingHeat Transfer Powder CoatingHigh Temperature Resistant Powder CoatingMetallic/Peal Powder CoatingZinc Rich Epoxy Primer Powder CoatingSpecifications1)Good film tough, 2)Strong impact resistance, 3)light color, excellent construction performance, good anti-corrosion ability

Variety and Performance:

Include high light, matt, sediment ripples, art-type pattern and anti-corrosion powder with different color. Good film tough, Strong impact resistance, light color, excellent construction performance, good anti-corrosion ability and excellent insulativity.

Application:

Suitable for all kinds of indoor products such as household appliances, instruments, meters medical devices, automotive components, metal furniture, fitness equipment, indoor decorative painting, etc., also apply to a variety of equipment, pipes, pipe fittings and other requirements of corrosion coating.

Powder physical properties:

Specific gravity: 1.4-1.7 (for color and gloss vary)

Particle size distribution: 100% less than 100 microns (based on the special requirements of coating adjusted)

Fluidity: 120-140

Curing condition:

Type A - 200°C (work piece temperature), 15 minutes (flat or Matt)Type B -180°C (work piece temperature), 15 minutes (highlight)

Type C -140°C (work piece temperature), 15 minutes (highlight)

Performance of film:

Inspection Item | Test Standard or Method | Test Indicator | |||

Type A | Type B,C | ||||

Impact resistance | ISO6272 | GB/T1732-1993 | 40cm | 50cm | |

Cupping test | ISO1520 | GB/T9753-1988 | 5mm | 8mm | |

Adhesion(Planning grid method) | ISO2409 | GB/T9286-1998 | Grade 0 | ||

Crook | ISO1519 | GB/T6742-1986 | 3mm | 2mm | |

Pencil hardness | ASTMD3363 | GB/T6739-1996 | 1H-2H | ||

Salt test | ISO7253 | GB/T1771-1991 | > 500 hours | ||

Heat test | ISO6270 | GB/T1740-1979 | > 1000 hours | ||

Heat resistance | 100°C/24 hours (white) | Paul Light character (best) : | |||

Remark | 1, The above test use cold-rolled steel(thichness:0.8mm) to remove rust,oil. Film thickness: 50-70um. 2, All the indicators of film features will be down lightly depending on reducing of luster. | ||||

Spreading rate:

9-12 square meters/kg Film thickness:60um(calculate as 100% powder coating)

Packing:

Paper carton lining to two Polyethylene inner bags. Net weight: 20kg/carton

Storage:

kept in dry and ventilating place, the temperature is less than 25°C, and far away from heat and fire. Avoid straight sunshine, do not place open air. Under these conditions: stable storage 6 months. When over storage time, retest it, if the results meet requirement, then can still use.

Health and Safety:

Although it is non-toxic products, the operator should wear mask and glass to prevent inhaling dust. Don't contact with this powder in long time

thermosteting spray metallic powder paint