- Paint & Coating[10]

- Polymer[2]

- Contact Person : Ms. Wang Terry

- Company Name : Jinhu Color Powder Coating Co., Ltd.

- Tel : 0086-25-57909280

- Fax : 025-57909280

- Address : Jiangsu,NANJING,Hua yuan Road 8#

- Country/Region : China

- Zip : 210042

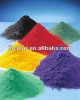

wood effect powder coating paint

Decorative wood powder coating is a heat transfer printing(sublimation) process, of which the decorative patterns is transferred into powder coated surfaces. It's suitable for indoor and outdoor products range.

Specifications1)Good film tough, 2)Strong impact resistance, 3)light color, excellent construction performance, good anti-corrosion ability

Variety and Performance:

Include high light, matt, sediment ripples, art-type pattern and anti-corrosion powder with different color. Good film tough, Strong impact resistance, light color, excellent construction performance, good anti-corrosion ability and excellent insulativity.

Application:

Suitable for all kinds of indoor products such as household appliances, instruments, meters medical devices, automotive components, metal furniture, fitness equipment, indoor decorative painting, etc., also apply to a variety of equipment, pipes, pipe fittings and other requirements of corrosion coating.

Powder physical properties:

Specific gravity: 1.4-1.7 (for color and gloss vary)

Particle size distribution: 100% less than 100 microns (based on the special requirements of coating adjusted)

Fluidity: 120-140

Curing condition:

Type A - 200°C (work piece temperature), 15 minutes (flat or Matt)Type B -180°C (work piece temperature), 15 minutes (highlight)

Type C -140°C (work piece temperature), 15 minutes (highlight)

Performance of film:

Inspection Item | Test Standard or Method | Test Indicator | |||

Type A | Type B,C | ||||

Impact resistance | ISO6272 | GB/T1732-1993 | 40cm | 50cm | |

Cupping test | ISO1520 | GB/T9753-1988 | 5mm | 8mm | |

Adhesion(Planning grid method) | ISO2409 | GB/T9286-1998 | Grade 0 | ||

Crook | ISO1519 | GB/T6742-1986 | 3mm | 2mm | |

Pencil hardness | ASTMD3363 | GB/T6739-1996 | 1H-2H | ||

Salt test | ISO7253 | GB/T1771-1991 | > 500 hours | ||

Heat test | ISO6270 | GB/T1740-1979 | > 1000 hours | ||

Heat resistance | 100°C/24 hours (white) | Paul Light character (best) : | |||

Remark | 1, The above test use cold-rolled steel(thichness:0.8mm) to remove rust,oil. Film thickness: 50-70um. 2, All the indicators of film features will be down lightly depending on reducing of luster. | ||||

Spreading rate:

9-12 square meters/kg Film thickness:60um(calculate as 100% powder coating)

Packing:

Paper carton lining to two Polyethylene inner bags. Net weight: 20kg/carton

Storage:

kept in dry and ventilating place, the temperature is less than 25°C, and far away from heat and fire. Avoid straight sunshine, do not place open air. Under these conditions: stable storage 6 months. When over storage time, retest it, if the results meet requirement, then can still use.

Health and Safety:

Although it is non-toxic products, the operator should wear mask and glass to prevent inhaling dust. Don't contact with this powder in long time

wood effect powder coating paint

Verified Information This information is Verified by Bureau Veritas and validity period is 2012/09/18 --- 2013/09/18 All the information below may covers both Gold Supplier and its related companies , Their Relationship will be affirmed according to china laws and regulations , also it will be clearly display in the full report >> Production Capacity:| Thermosetting Powder Coating | 110,000 KGS Per Month | 1,150,000 KGS |

| North America | USD 50,000 | 0.98 |

| South America | USD 150,000 | 2.95 |

| Eastern Europe | USD 1,500,000 | 29.47 |

| Africa | USD 150,000 | 2.95 |

| Mid East | USD 2,400,000 | 47.15 |

| South Asia | USD 90,000 | 1.77 |

| Domestic Market | USD 750,000 | 14.73 |

| Mixer | YUANLI, Siemens | 4 | 3.0 | Acceptable |

| Extruder | YUANLI | 4 | 3.0 | Acceptable |

| Chipping Machine | YUANLI | 4 | 3.0 | Acceptable |

| Milling Machine | YUANLI | 4 | 3.0 | Acceptable |

| Laser Particle Size Analyzer | LS-POP | 1 | 0.1 | Acceptable |

| Color Assessment Cabinet | CAC-600-6 | 1 | 2.0 | Acceptable |

| Coating Thickness Gauge | TT220 | 2 | 2.0 | Acceptable |

| Gloss Measurement | KSJ | 2 | 2.0 | Acceptable |

| Color Reader | CR-10 | 1 | 2.0 | Acceptable |

| Elasticity Tester | QTX | 1 | 3.0 | Acceptable |

| GB/T19001-2008 | NGV, CNAS | 05312Q21762R0S | Production of Powder Coating(Export Sales) | 2012/08/01 --- 2015/07/31 | |

| GB/T24001-2004 | NGV, CNAS | 05312E20308R0S | The Environment Management Activities of Concerned Department, Office Area and Working Station of Production of Powder Coating(Export Sales) | 2012/08/01 --- 2015/07/31 |